Analysis & characterization

Understanding material properties and their link to structure and processes

In order to design new materials – or improve existing ones – it is necessary to characterize them and obtain insight into how processing parameters influence structure and properties. M2P can provide a wide variety of testing platforms as well as analysis and characterization facilities for this need: chemical, physical, thermal, microstructural, mechanical and dimensional for metals, metal powders, multi-material assemblies and composites.

Our equipment also reproduces the thermal, chemical and mechanical stresses encountered under industrial conditions, in order to better understand and improve materials.

Expertise & services

- Characterization and analysis equipment are used in our collaborative projects, and are also available on-demand for private research

- Resources and skills for punctual or regular analyses for industry or academia

- Development of reliable methods to monitor and control processes, improve their performance, and guarantee the quality of the materials produced

- Interpretation of results by a group of experts in the field of chemistry, metallurgy, mechanics and physics

- Analysis & Characterization is cross-sector and involve all activities at M2P

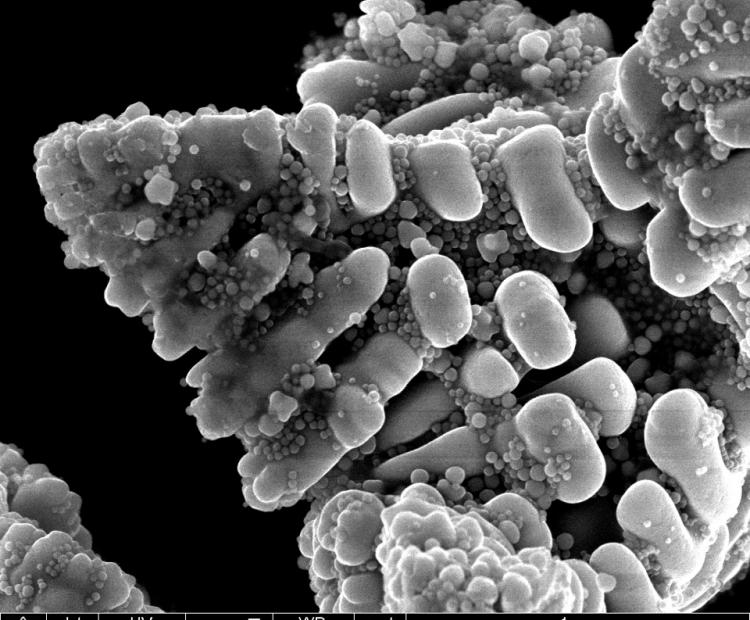

Metal Powders Characterization

Flowability by Hall and Carney

Particle shape and size analysis: dynamic image analysis and Keyence microscopy

Chemical analysis by X-ray fluorescence, ICP-OES

Dissolved gas analysis: ONH, CS

Sample preparation/handling

Access to a network with additional testing

Mechanical & Dimensional Characterization

Hardness measurement with macro / microdurometer

Coating adhesion measurement by indentation

Mechanical tests: quasi-static tension-compression instrumented tests on metals, composites, multi-material assemblies

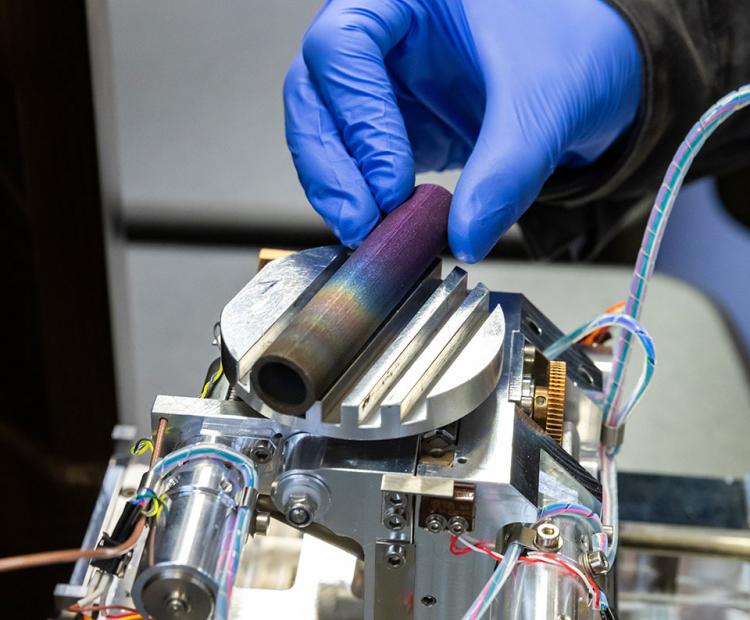

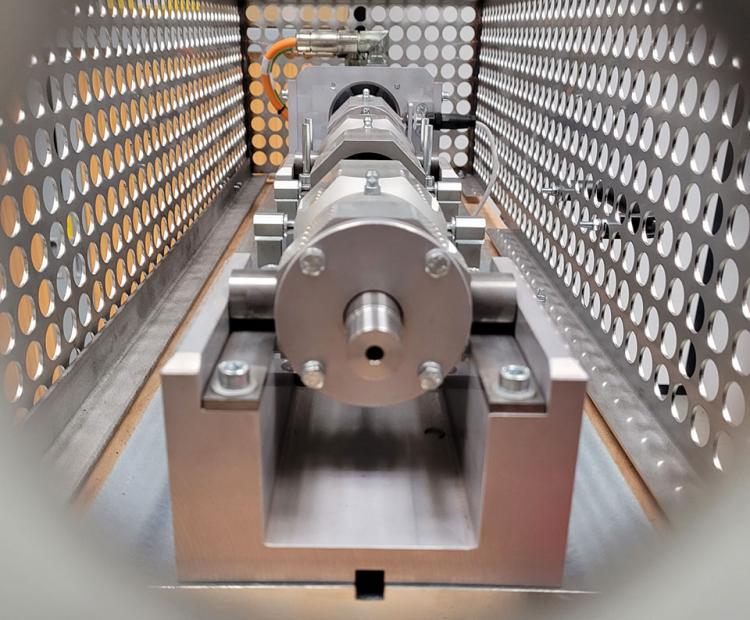

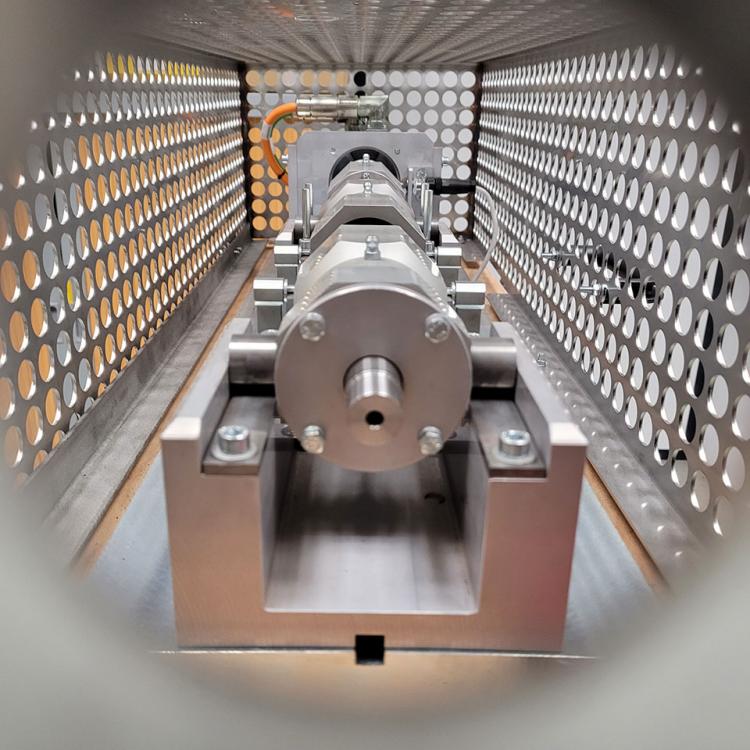

Fatigue tests on metals, composites, multi-material assemblies using a servo-hydraulic mechanical testing machine : Cyclic tension-compression, Wöhler curves (SN or FN curves), creep

Instrumentation of tests with third-party means (thermal camera, etc.)

Rotational bending fatigue tests (Qualification by Airbus Helicopters)

Tribological tests – Taber

3D measurements with 7-axis measuring arm

3D probing and 3D scanning for the digital reproduction of the geometry of all types of metal parts, textile preforms or composite parts

Geometric differences between CAD model and real part

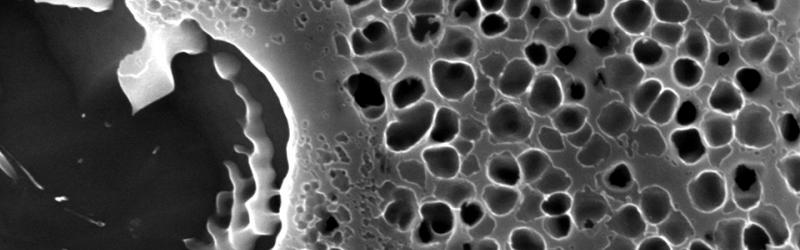

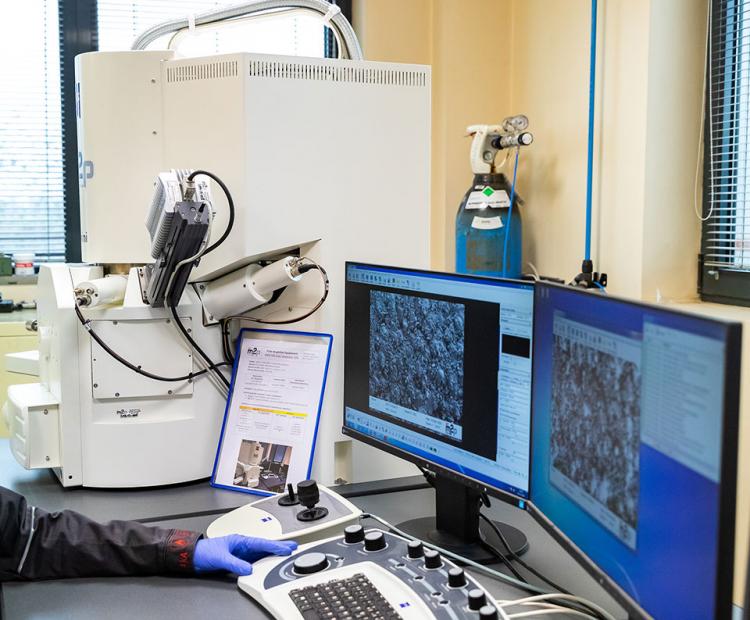

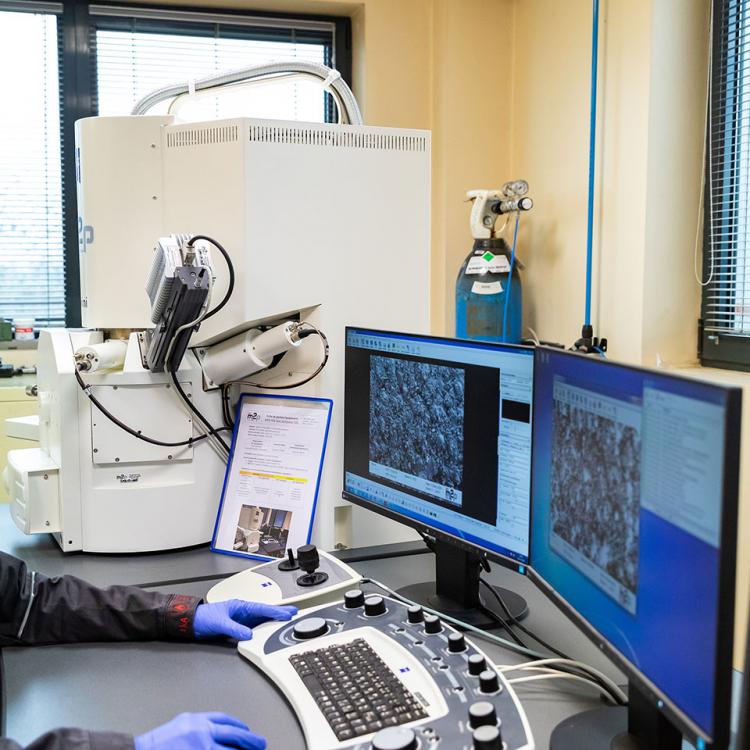

Microstructure Analysis

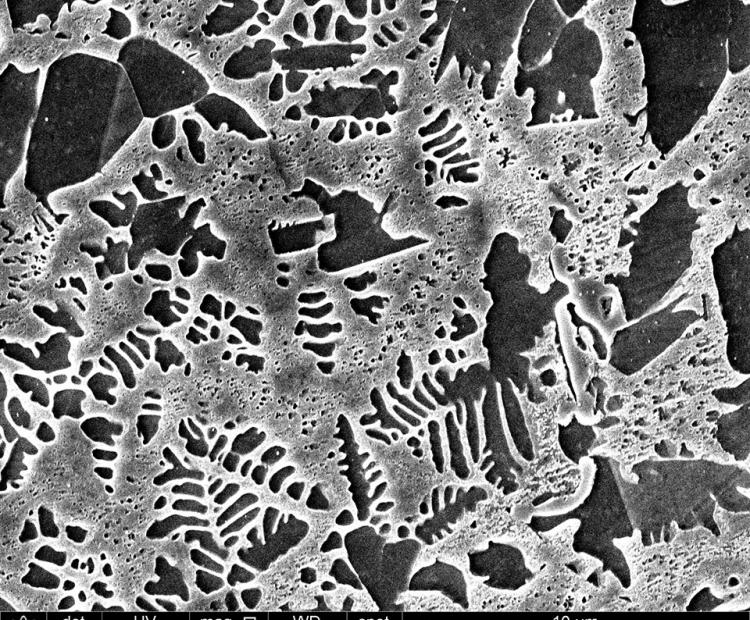

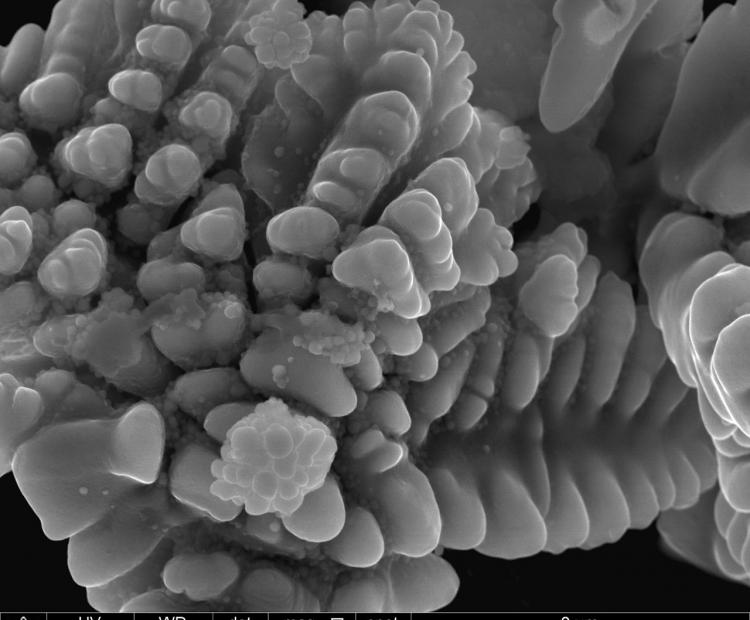

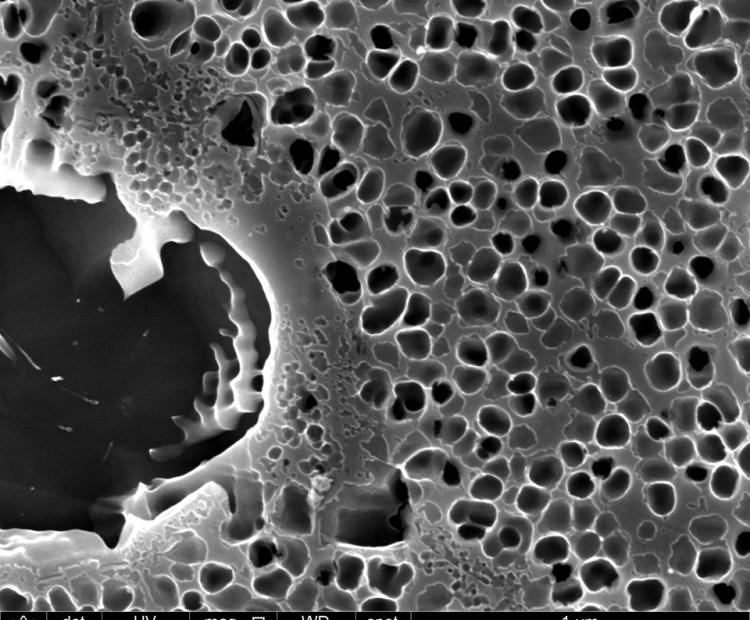

Metallographic preparation (cutting, hot mounting presses, mechanical and ionic polishing)

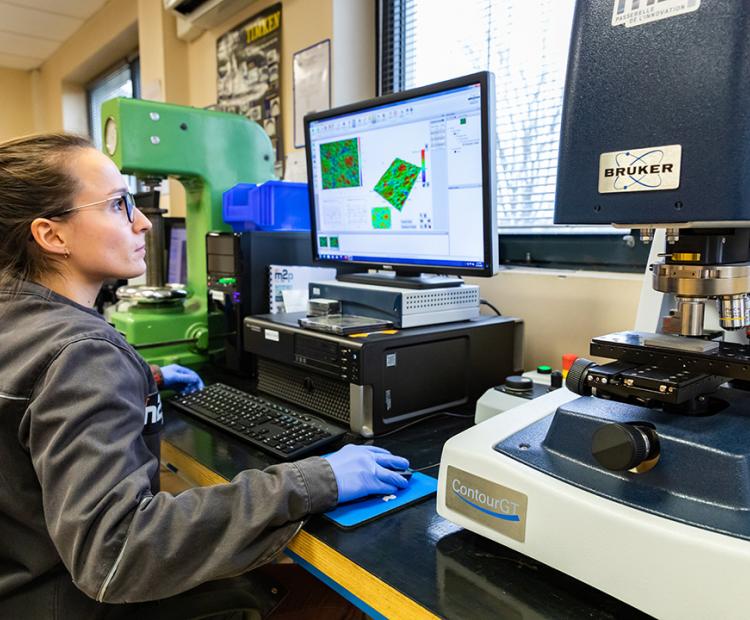

Different scales microscopies: Binocular, Optical and Secondary Electron Microscopy (SEM FEG)

Topographic surface measurements: 3D digital microscope, Interferential microscope, Optical profilometry, Roughness meter

Thickness measurement of coatings and surface layers: Coulometric methods, non-contact and non-destructive measurement ENOVASENSE®

Measurement of closed porosities, detection of coating adhesion problem

Physical & Chemical Analysis

Solid-state chemical composition: Optical emission spectrometry, X-ray fluorescence (XRF), SEM-EDX, Glow discharge spectrometry

Chemical composition of solutions: ICP-OES, electrochemistry

Dissolved gas analysis: ONH, CS

Corrosion resistance: salt spray, electrochemistry

Crystallography - XR diffractometer

Characterization of the electrical conductivity of coatings