Presentation

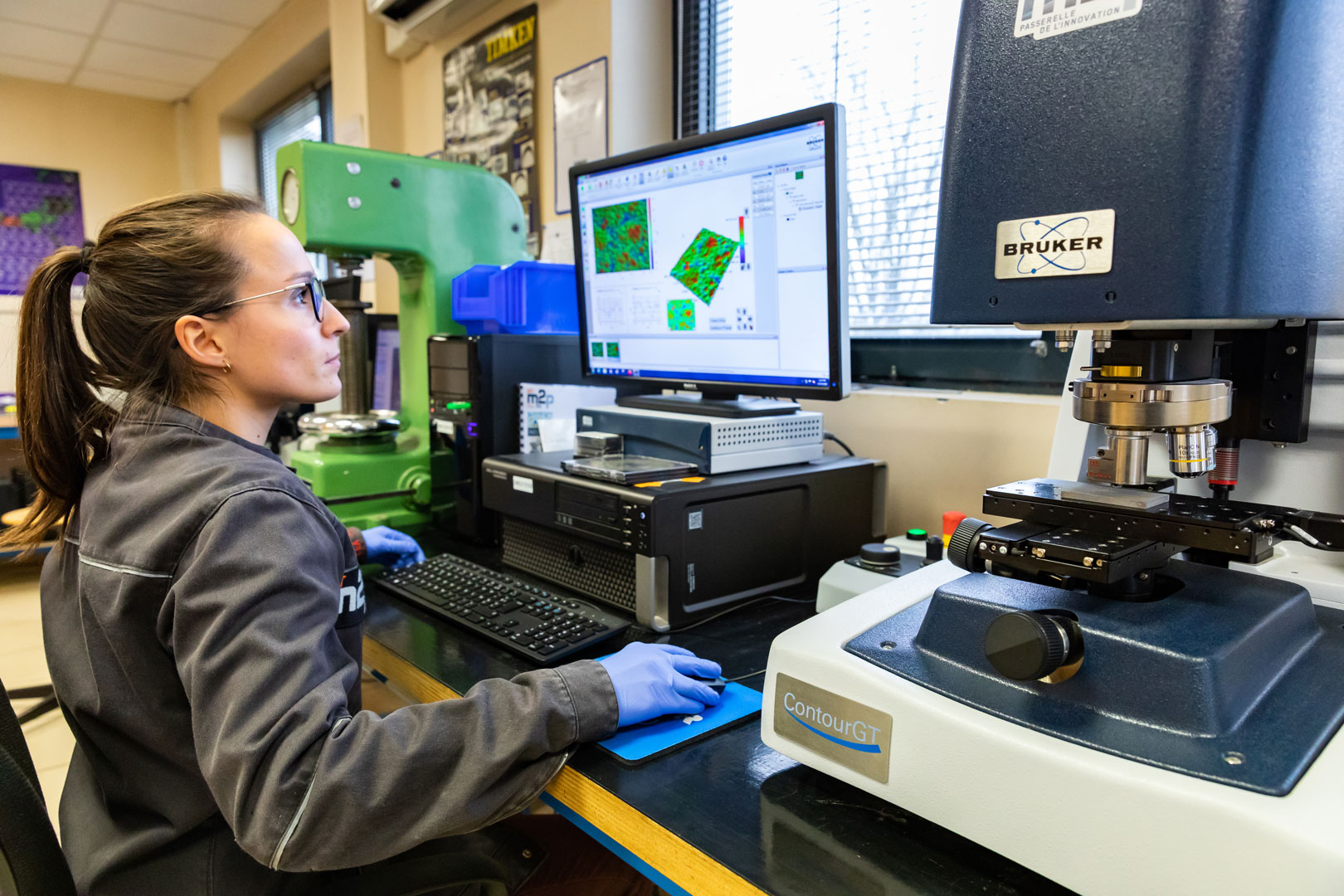

Here at the Institute for Technological Research into Materials, Metallurgy and Processes (IRT M2P), we put our expertise, equipment and network of academic laboratories to work for R&D projects in collaboration with industrial actors.

Among other things, IRT M2P’s semi-industrial pilot equipment enables faster product and process development in an environment representative of real-world constraints. Combining developments from technology suppliers, manufacturers and end-users operating in different lines of business also accelerates the process of bringing innovations to maturity via IRT M2P.

All industrial partners can benefit from the range of technologies and platforms available via customised services, private R&D projects or multi-partner projects with joint funding from the public/private sector. IRT M2P’s resources are also available for vocational training.

IRT M2P is partially funded by the French government’s ”invest in the future” programme, the Programme d’Investissements d’Avenir (PIA), with attractive co-financing of industrial RDI projects

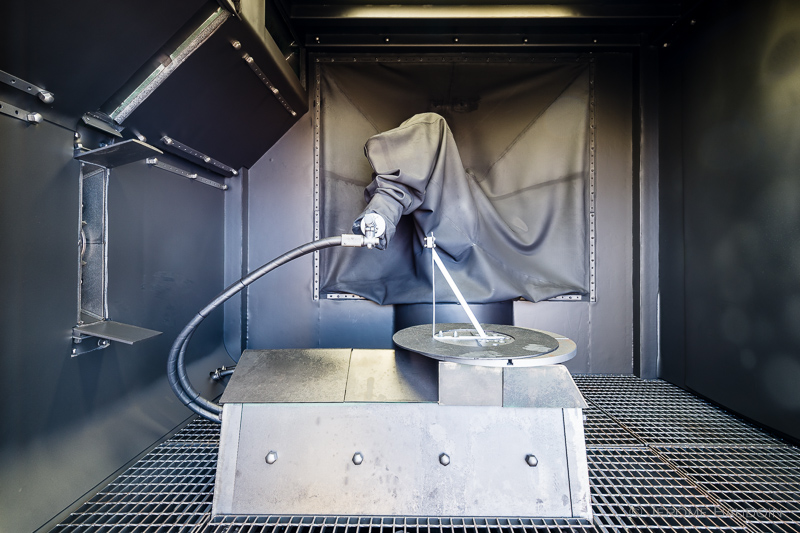

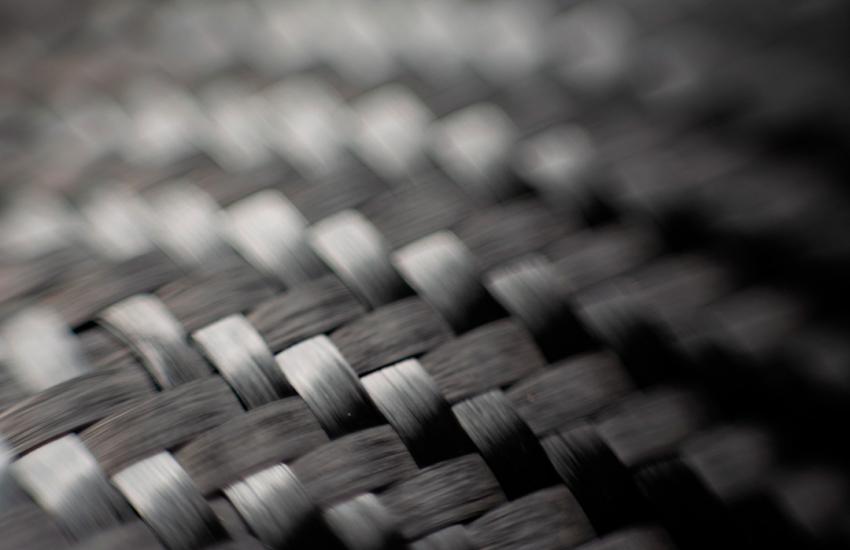

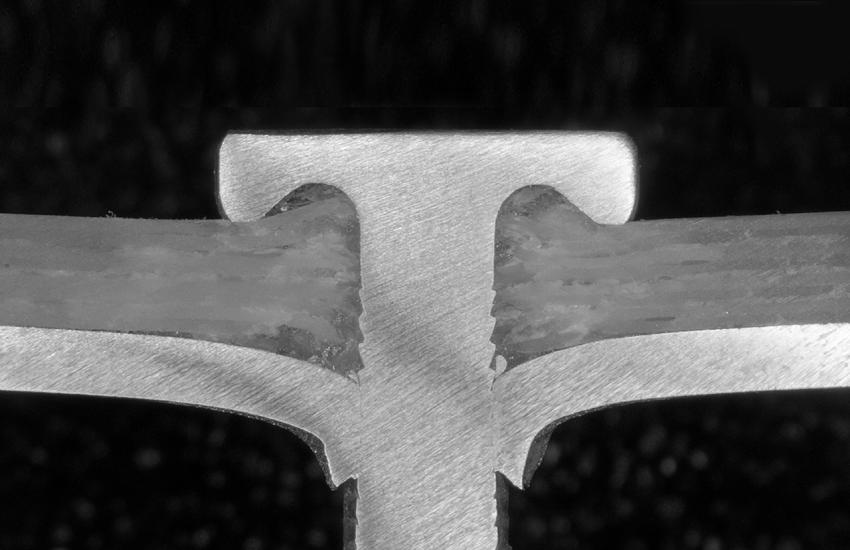

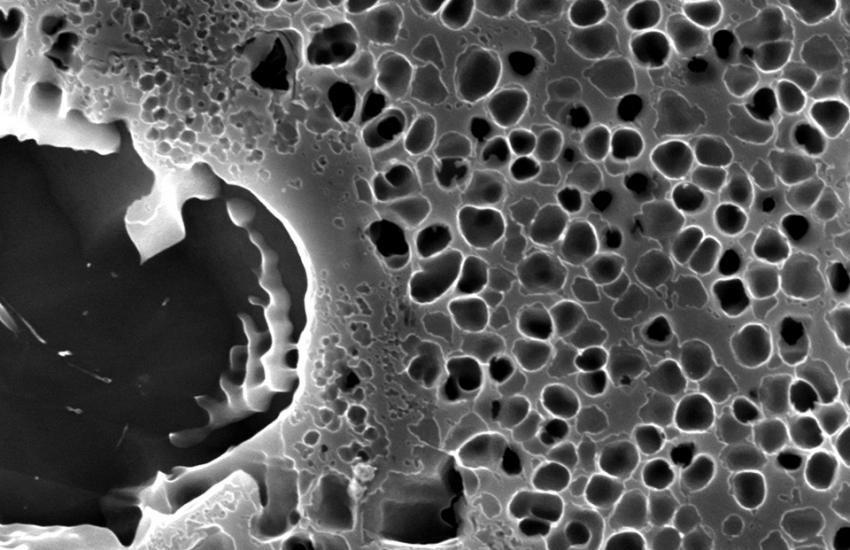

Our work encompasses the entire materials production chain (whether metal or organic matrix composites): from their development and, of course, their recyclability, to the manufacture of products that combine several materials to obtain the desired function. In particular, this includes production processes in the context of sustainable development (energy savings, using fewer raw materials, having a minimal impact on the environment).

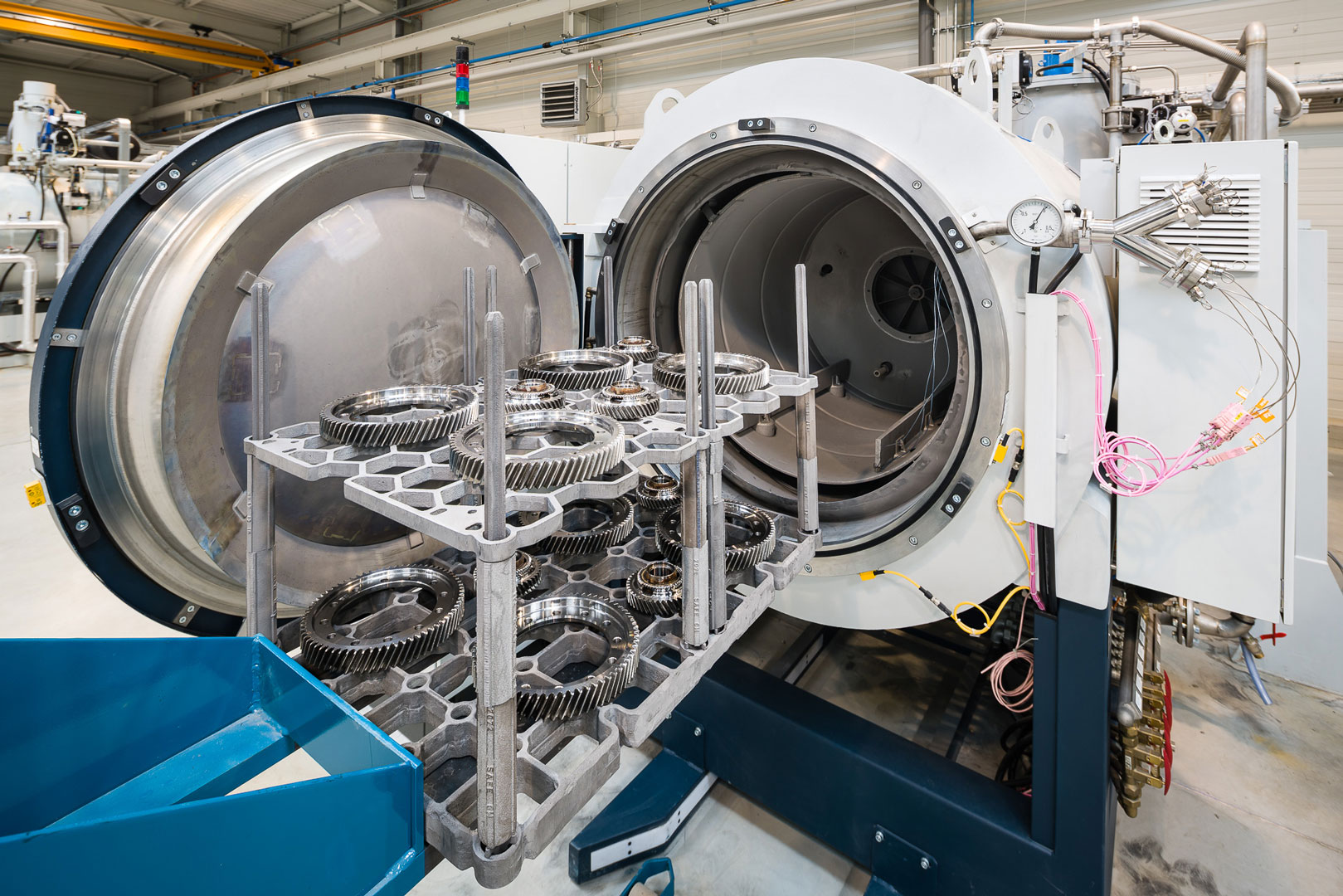

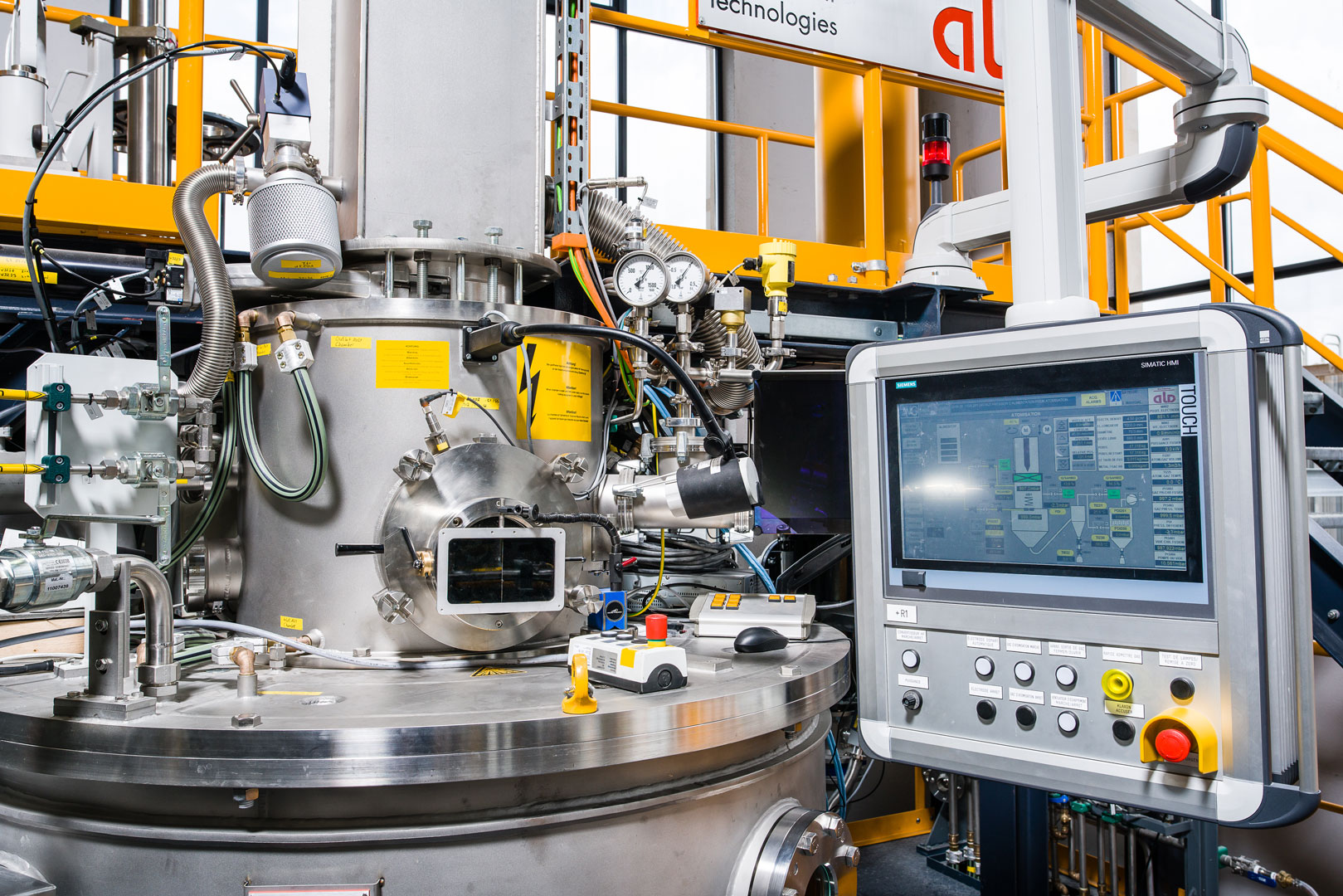

Our line of business is structured into three main areas: Melting & Casting, Surface Treatment, Composites & Assembly.

These areas take the form of nine fields of expertise that can be combined to meet the needs of one of many projects.

We have a large range of technologies on offer, whether in terms of size (representative of an industrial scale), the concentration of ‘standard’ resources equipped with instruments and combined, or the integration of disruptive technologies. The platforms take into account the needs of technology providers, manufacturers and end-users in terms of productivity, repeatability, reliability, quality and robotisation and are the building blocks of the factory of the future.