Life cycle assessment & recycling

Support and services for the environmental transition

New materials can contribute to the environmental transition thanks to improved properties and innovative applications. However, the processes used to produce them come with a non-negligeable environmental impact.

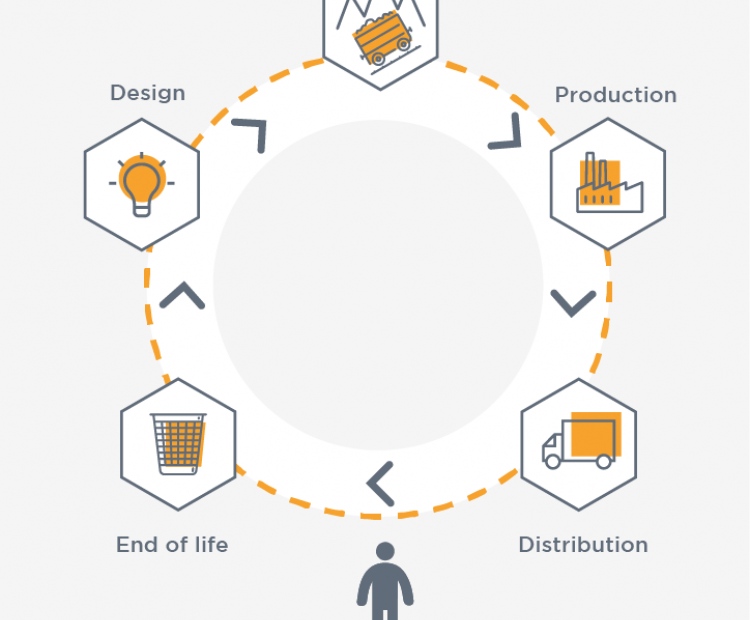

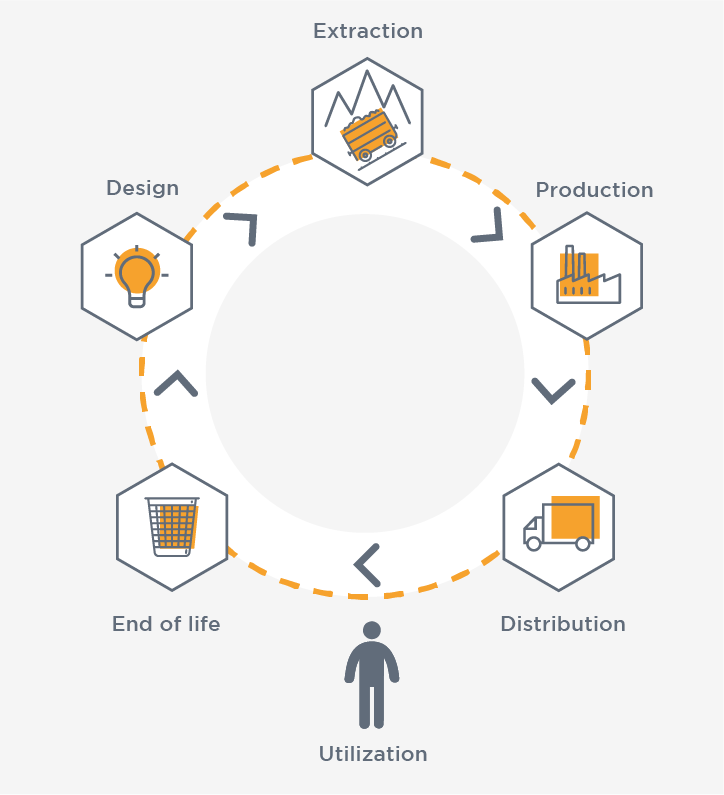

Evaluating this impact, identifying ways to reduce it and improving industrial processes is thus crucial. M2P’s contribution to a new circular economy is through our activities in life cycle analysis, material flow analysis and increasing the use of recycled materials while maintaining material quality.

Increasing the use of recycled materials

Giving materials new life at the end of their initial use

- Evaluation of attainable recycling rates via the study of secondary materials from various dismantling and shredding processes

- Improvements in sorting and separation technology for metallic materials

- Analysis and characterization of scrap quality in order to evaluate compatibility with various metallurgical specifications

Converting scrap into high quality metals

- Creation, with industrial partners, of the first operational titanium scrap recycling loop in Europe

- Evaluation of various scrap grapes with respect to existing and future pyrometallurgical processes

- Recycling metallic powders from additive manufacturing

Evaluating the environmental impact of materials

Life Cycle Assessment (LCA)

- Life-cycle inventories (LCI) and material and energy balances followed by a complete LCA for products and processes according to ISO 14040/14044

- Complete LCA databases with reliable data thanks to modeling and the in-house availability of semi-industrial scale platforms as well as our knowledge and experience in metallurgical processes

- Environmental Product Declarations (EPD) in order to communicate clearly and compare the environmental impact of products over their entire life cycle

- Identification and evaluation of the various technical or technological levers for improving the environmental footprint of industrial processes

Materials Flow Analysis (MFA)

- Material and energy flow analysis at various scales (process, production chain, regional, national, international) to identify the principal axes of production, use and loss

- Production process optimization in order to reduce material consumption and loss

- Use of MFA as a predictive tool in order to forecast future material availability and, thus, anticipate opportunities for recycling and reincorporation

- Reduce “downcycling” by identifying high potential material flows and developing the technologies necessary to maintain their quality during recycling

Resources @M2P

LCA and MFA software

GaBi – Thinkstep

Umberto® - ifu Hamburg GmbH

Specialized databases

GaBi Professional

GaBi specific databases on materials

Ecoinvent 3.5

Standards

ISO 14040 – 14044

ISO 14020 – 14025

NF EN 15804

Instrumented lab- and pilot-scale technological platforms for data collection and model validation

Support in the environmental transition

Product LCA: optico-electronic systems, construction materials, 3D printed products, various products containing metallic and composite materials

Process LCA: verifying the potential environmental consequences associated with substituting surface treatments for REACH conformity, thermal spray processes, forming processes for metals and composites

MFA: support industrial actors wanting to better recycle their products by mapping out actors in the materials flow chain (production, use, end-of-life) combined with analysis of mediumand long-term trends for production and recycling