Mechanical surface treatment

Improving mechanical properties through compressive residual stresses

Dimensional control and performance specifications for metallic parts are increasingly strict meaning that processes, such as shot peening, need to be continuously improved. These processes must also be adapted to newly developed alloys.

Through the study and understanding of surface strengthening and damage mechanisms, including numerical simulation of residual stresses, IRT M2P improves existing processes and helps develop new ones. Experienced in the aerospace, automotive, marine and other sectors, IRT M2P deploys its industrial-scale equipment and know-how in the field of shot peening and mechanical surface treatments.

Expertise & Services

Mechanical surface strengthening

- Access to a flexible platform equipped with various sensors

- New shot development

- Process development and optimization

- R&D and industrial support for shot peening

- Adaptation of shot peening parameters with respect to product specifications

- Assistance with integrating shot peening with other processes

- Robot trajectory programming and evaluation of effective zone

Process supervision

- Automotive and aerospace standards

- Precise determination of Almen intensity and covering ratio

- Pressure and mass flow monitoring

- Shot speed monitoring by Shotmeter®

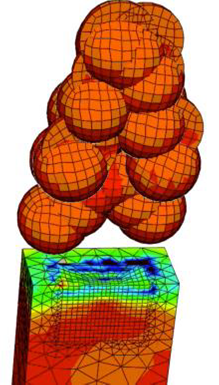

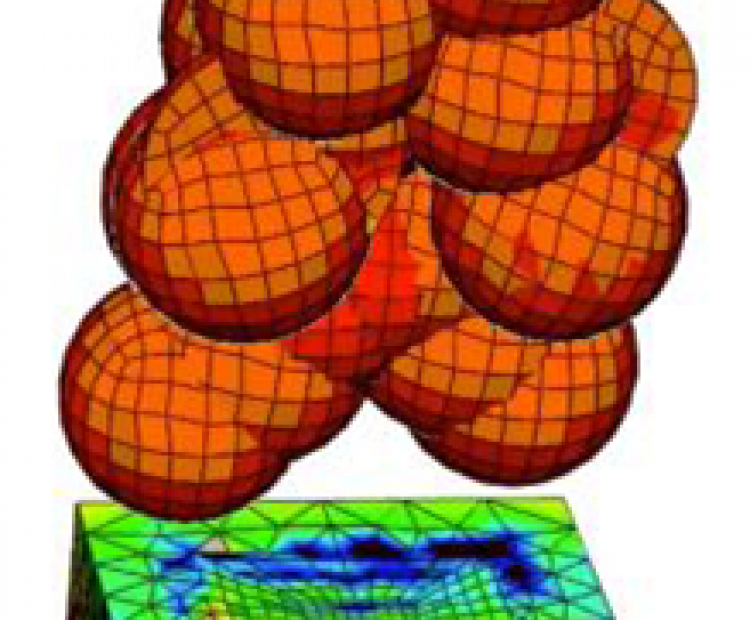

Process simulation and modelling

- Part design including shot peening

- Predict residual stresses under solicitation

- Parametric studies and model definition

- Process simulation using a multi-shot model: projectile speed, angle, shot size, covering ratio, material characteristics

Analysis & Characterization

- Surface integrity

- Residual stresses analysis

- Mechanical properties

- Microhardness profile

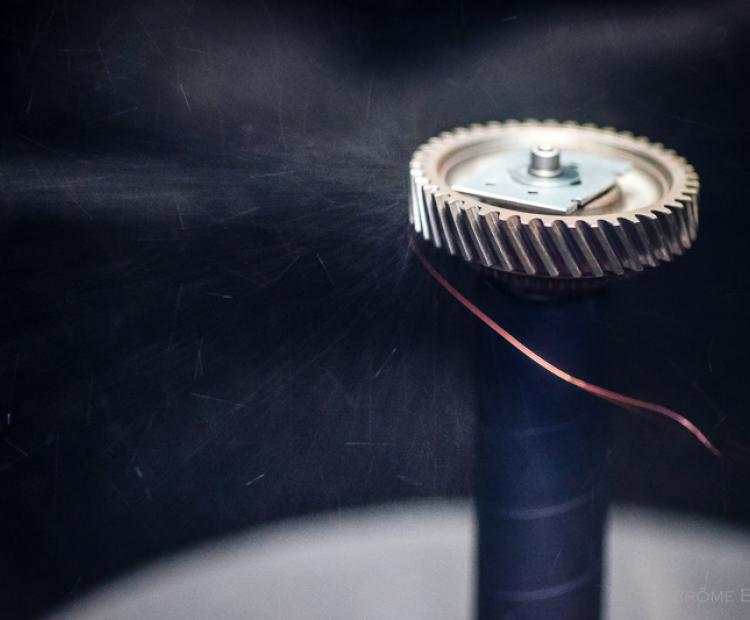

Technology

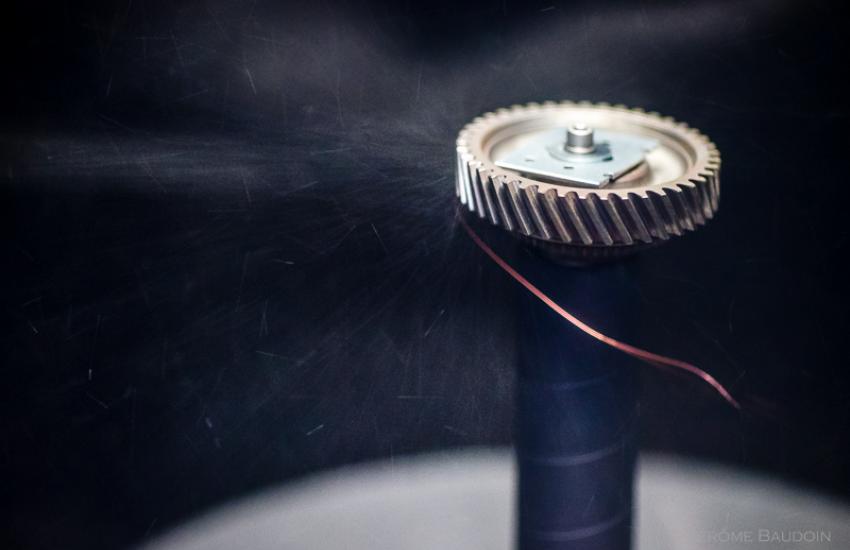

Shot peening process by:

Nozzles: Precise and controlled application including difficult-to-reach zones

Turbine: High intensity, adapted for full-scale production

Specially designed tool to project shot within bores (turbine rotor, pipes/tubes, etc.)

Compactage de revêtements organiques

Laser Shock Peening :

No surface contamination (in situ operation, no post treatment, etc.)

Deeper and more intense residual stresses profiles

Precise treatment zones

Laser via optical fiber or air

Equipment @M2P

Shot peening platform

2 shot peening machines

6 axis robot

Nozzle diameters: 4, 10 and 20 mm

Bore stick: 1 800 mm

Rotating table

Shot sieving and separating

Wide selection of shot: Cast steel, Cut wire, ceramics

Monitoring - Shot speed (Shotmeter®) - Offline robot trajectory - Pressure and mass flow

Laser shock peening platform

6 axis robot

Laser beam: 1 J to 1064 nm

Pulses: 5 to 20 ns

Water containment, or other

5 m long optical fiber

Optical fiber cleanliness monitoring during use

Applications

Use of design-of-experiments to optimize shot peening parameters for titanium alloys in order to maximize fatigue enhancement and strike a balance between residual stresses and surface integrity

Impact of shot peening on maraging alloys and process optimization

Laser shock peening for in situ repairs

Examples: Bearings, springs, wheels, landing systems, turbine disks and blades, Weld seams, etc.